How Can You Manage What You Don’t Measure?

The HVAC system can be viewed as the respiratory system of a building, supplying conditioned air to all areas. The air handler is the lungs of the system since this is where outdoor air is drawn in, filtered, conditioned, and mixed with return air. This “supply" air is then distributed through a network of ducts to and from areas of the building. Basic components include dampers, fans or blowers, heating and cooling coils, air filters, boilers or furnaces, compressors, ductwork to convey the air and diffusers or registers to distribute the air evenly. A number of controlling mechanisms, including thermostats, sensors and actuators, help control the distribution of air throughout a building.

Over time, “dirt, dust, debris" can lead to the demise of an HVAC system. At a minimum, unwanted contaminants can inflict damage to equipment that leads to premature wear and tear, increased maintenance costs, increased cleaning costs and lower operating efficiency.

Therefore, it is critical to be aware of the system’s condition and components, to prioritize routine cleaning, minor repairs, and plan for the future. This will extend equipment life and provide visibility into AHUs that need to be replaced, leading to significant capital avoidance! HVAC Assessments also help your facilities stay compliant with ANSI/ASHRAE 62.1, 8.1 Operations and Maintenance.

Depending on Scope, HVAC Assessments Include

- AHU nomenclature, design & use verified

- Visual conditions noted & photographed

- Operational & performance data recorded

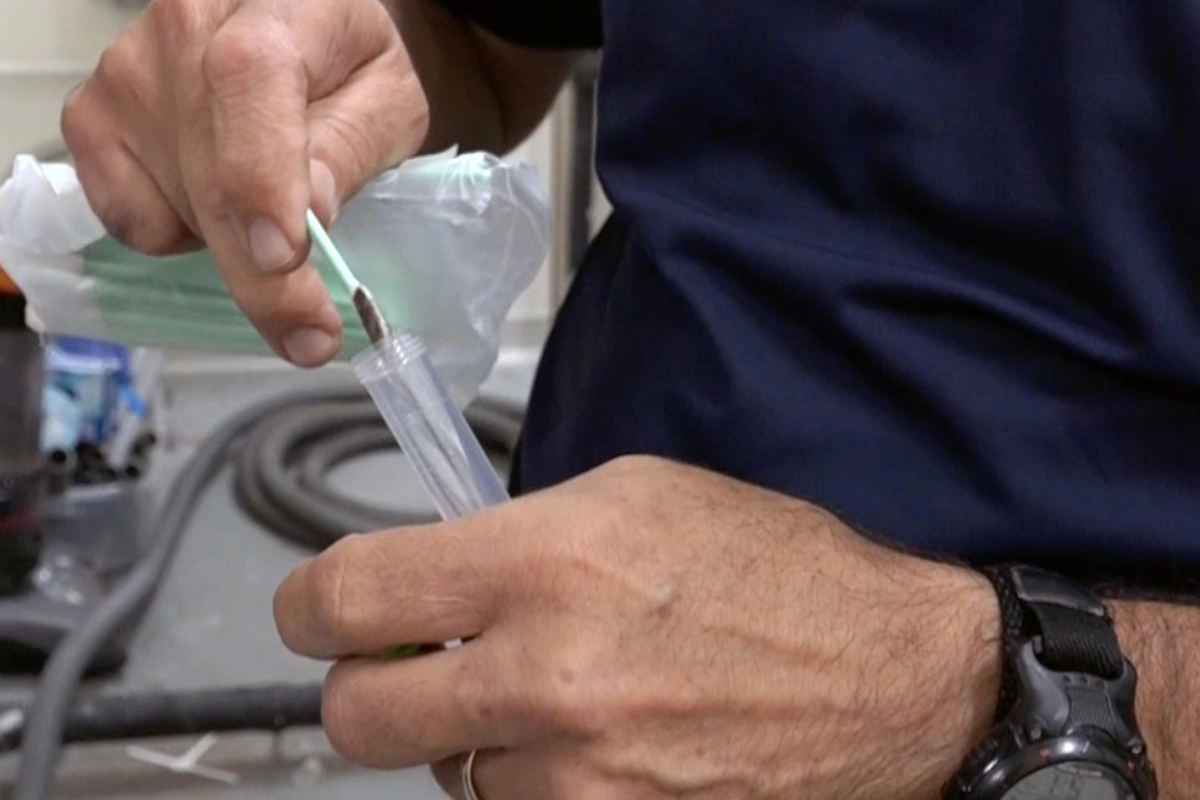

- Environmental samples collected & analyzed

- Report issued for all scopes with recommended corrective action

- 3-to-5-year capital plan

HVAC Assessments and Reporting Steer Corrective Action

We will visually evaluate your HVAC System, paying close attention to the condition of the air handler unit (AHU), evaporator coils, pan, rails, and blower. Our primary interest is to detect signs of allergens. We will also look at the ducts for microbial growth, dust, debris, or other obstructions.

We can perform tests for differential pressure across the coil, relative humidity, allergens, microbial growth, Legionella and more. Plus, both air and surface samples can be collected from the HVAC system for analysis. We also offer total air handler and system performance evaluations, including electrical usage, fan RPM, cooling output in BTU, chilled water volume usage in GPM, and smoke detector differential testing.

Samples collected from the AHU are sent to an accredited environmental laboratory for expert analysis. They will identify and quantify any contaminants of concern in the HVAC system. This analysis helps determine the impact it could present on your facility. The data that’s provided is integral to creating a scope for corrective action.

You will receive a detailed yet easy to understand report. The report is photo-documented and contains a glossary for reference. It helps prioritize a plan for corrective action to remedy any issues found. The report can also be used to illustrate the gains made through remediation. Upon request, a multi-year capital savings plan can be supplied using the data collected from a full HVAC Assessment.