Need help finding the right product or a service?

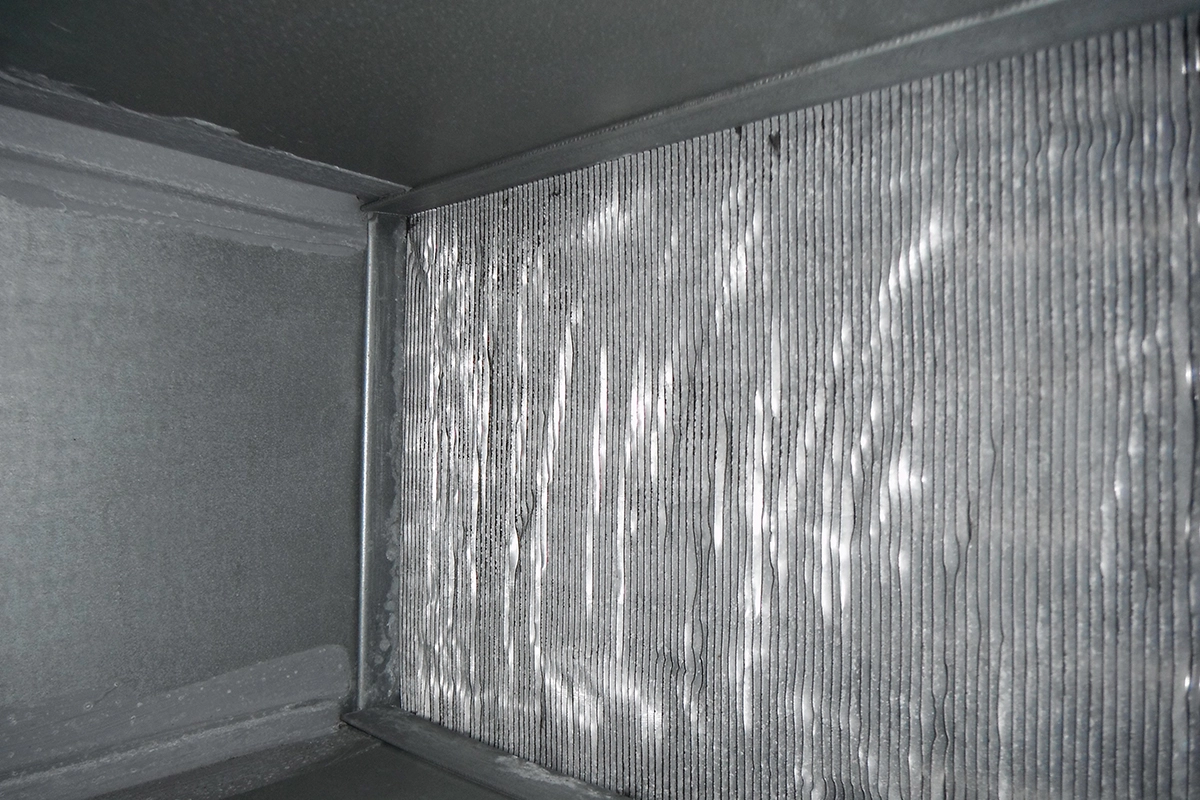

Comprehensive Duct Cleaning for Optimized Air Quality

Clean ducts reduce allergen triggers and increase productivity. Did you know that one out of six occupants suffer from allergies triggered by bacteria and fungi spread throughout a building by the ductwork? Allergy and asthma attacks can cause disruption and even absence. A recent Harvard/SUNY study on the benefits of good Indoor Air Quality (IAQ) has shown that an increase in clean indoor air can improve the cognitive function of the occupant by 15% or more!

Best in Class Service

Have your ducts cleaned by the best in the business? We are a mechanical contractor and an active member of the National Air Duct Cleaning Association (NADCA). Your HVAC system is in safe hands. With over 30 years of expert experience in commercial and residential duct cleaning, plus an extensive network within the HVAC industry, WTI Pure Air Control Services is the company you can trust. Clean your system without a mess! Our technicians are held to the highest standard in the industry with extensive training and a commitment to adhering to each job’s detailed specifications.

Healthcare facilities require extra care for duct cleaning and other remediation projects. We understand the regulatory framework healthcare facilities operate within. WTI Pure Air has many years of experience complying with The Joint Commission and each hospital’s ICRA to get the job done right under the most stringent specifications.

Engineered Steps for Successful Projects

Before the physical cleaning begins, we study the mechanical prints and conduct a visual inspection. These are critical to understanding how the system is designed so that a plan can be outlined, access points determined, and containment protocols established. Containment in and around the sections of ductwork being cleaned (including duct smoke detectors) is integral to a hygienically successful outcome. We take great care to prevent cross-contamination during the cleaning process. Specialized methods are utilized like airtight physical barriers, traditional masking, and negative pressure work carts.

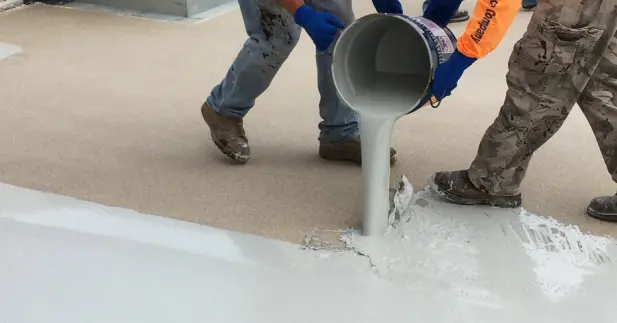

After the section area is contained, the duct can then be accessed. Methods vary depending on the type of ductwork. Most commonly, a small panel is cut. However, we can also install doors for ease of access in the future. Typically, access is needed for every 20 linear feet of duct to be cleaned. Next, a HEPA filtered negative air machine is installed on the section. This pressurizes the ductwork to powerfully vacuum dust and debris that is agitated during the cleaning process. Negative pressure is one of the important factors to prevent cross contamination in the building.

Once the section is under negative pressure, the cleaning can commence. We utilize a variety of tools depending on the physical size and type of duct being serviced. Most often it’s a combination of compressed air with a reverse flow nozzle and a Roto brush application. Each section is worked towards the negative air machine, pushing dust and debris into the immense HEPA vacuum. Where applicable, the ductwork is crawled and cleaned by one of our professionally trained technicians. This allows for a detailed visual inspection while cleaning to guarantee a more thorough outcome.

Measurement and verification testing is conducted before, during and after the PURE-Duct service. Samples are collected to identify contaminants present before cleaning and again after to ensure conditions are improved. During the cleaning, particulate counts can be monitored outside of the containment areas to check for cross contamination. After all access points are closed, the ducts are tested for leakage. Finally, a comprehensive report is issued that includes all logged data and photos and recommendations for other solutions to issues that might have been observed during the service.