A Sustainable Solution With Significant Capital Avoidance

By conducting conditional and performance assessments of AHUs, a clear plan can be adopted to replace only those that are at critical failure. Therefore, the HVAC New Life restoration service can preserve the balance of the new and restored equipment to free up precious capital for other projects. In some cases, as much as 70% cost avoidance compared to new equipment book cost. HVAC New Life restoration features a five-tiered suite of services that cleans, refinishes, and retrofits an AHU. It is performed in phases over a few days and outside of normal business hours to minimize disruption to the facility and its occupants.

Sustainability and Economic Outcomes

Many air handler units are located on the roof, allowing HVAC restoration to serve as the perfect complement to roof restoration as a bundled service. Even at other locations, restoration also allows air handlers to be “restored in place" to minimize time, labor and disruption.

Carbon free building initiatives, supply chain disruptions and rising fuel costs are other incentives to opt for HVAC New Life to manage these assets. Altogether, HVAC New Life reduces energy costs and the carbon footprint associated with the installation of new equipment and disposal of old AHUs.

All told, HVAC New Life reduces energy costs and the carbon footprint associated with the installation of new equipment and the disposal of the old AHUs.

Steps for Increased HVAC Lifespan

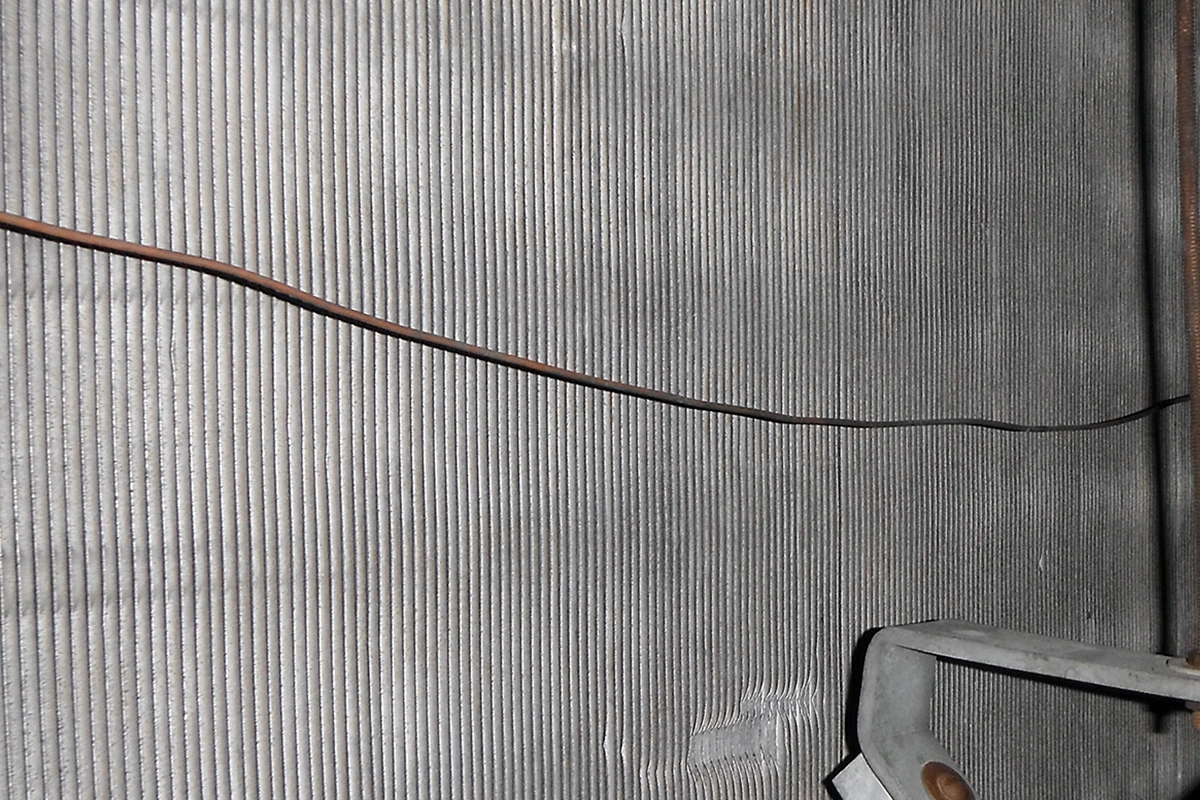

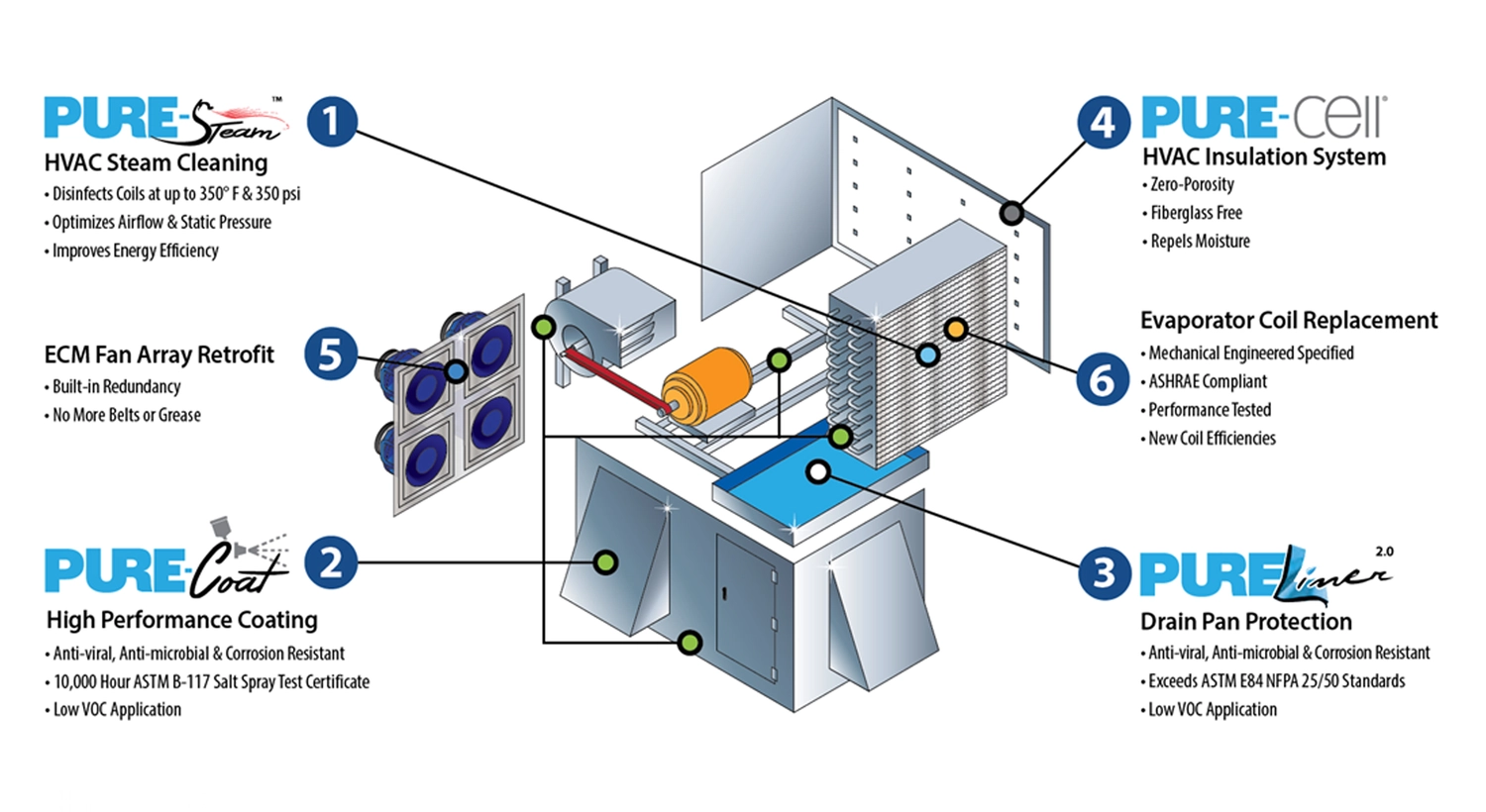

PURE-Steam uses steam up to 350-degree Fahrenheit at 350 psi to disinfect the interior of the unit and restore airflow through the chilled water evaporator coil. Over time debris collects across and within the coil. This not only restricts airflow, but also insulates the coil which leads to the blower running longer to achieve cooling. An EPA study found that just 3/16” debris across the coil can reduce efficiency by 21%. This creates a domino effect to the entire chiller loop. PURE-Steam effectively removes coil obstructions and restores energy efficiency to the system.

All metal components are prepared, primed and then refinished with PURE-Coat. This high-performance coating is designed and certified to be applied within the air conveyance system. PURE-Coat is a two-part, multi-siloxane paint that is hydrophobic and anti-microbial. It has been rigorously tested for performance and safety. PURE-Coat has both interior water-based and exterior solvent-based applications and is flexible to withstand the rigors of HVAC operation. PURE-Coat effectively restores the air handler metal to better than new conditions. Whereas many new AHUs either come with simple exterior coating only or no coating at all.

Condensate or drain pans are refinished with PURE-Liner high-performance coating. PURE-Liner is a similar, more viscous, version of PURE-Coat. It utilizes the same multi-siloxane base and is also corrosion resistant and anti-microbial. These pans catch the latent condensation from the coils and drain it from the air handler. Drain pans tend to be the most corroded part in an AHU and will often harbor bacteria and other microbes. PURE-Liner refinishes and protects drain pans from these concerns.

Exposed fiberglass insulation in an air handler poses risks to indoor air quality for two reasons. First, damp fiberglass insulation sags, becoming loose and leaking harmful environmental particles through the airstream and into the occupied space. Second, fiberglass is porous and can harbor microbes like bacteria and mold. If the AHU has exposed fiberglass insulation it will be safely and environmentally removed. Then PURE-Cell, fiberglass free, closed cell, insultation is installed. It is water resistant and has the same insulative, acoustic and fire safety properties as fiberglass. But it will not break down and is easy to maintain.

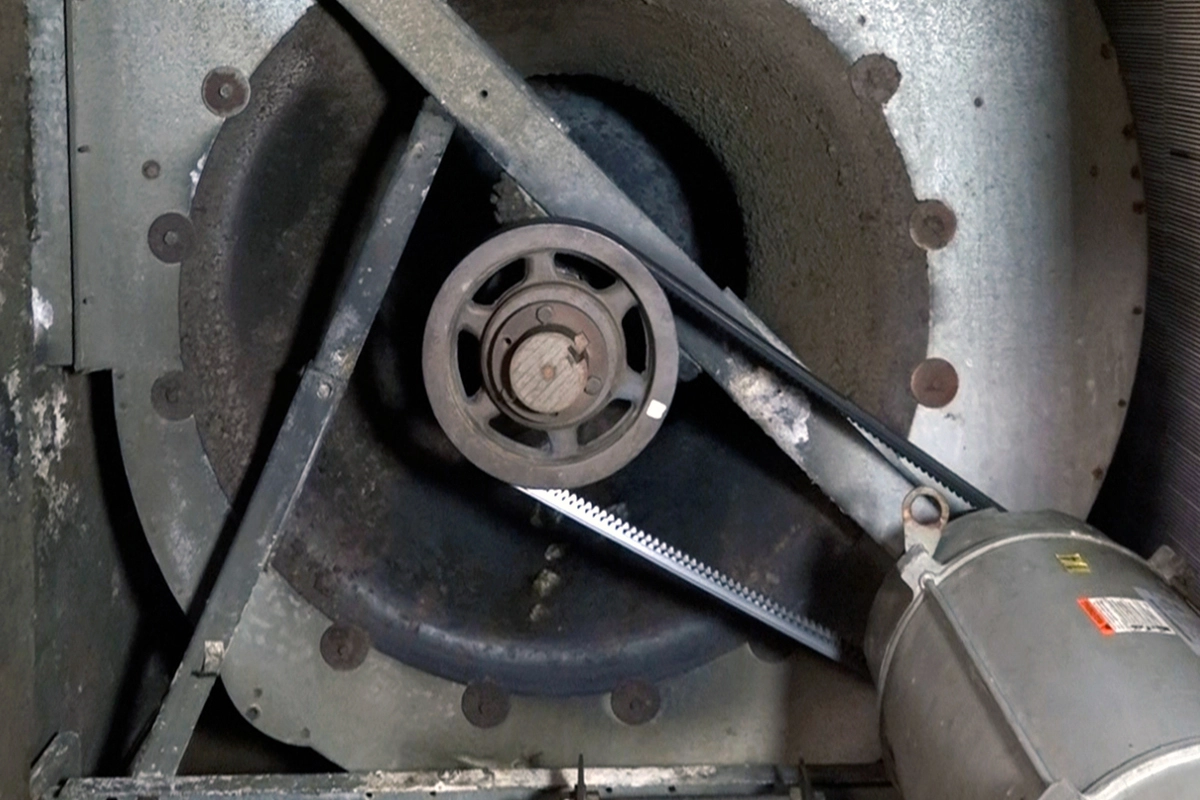

HVAC Fan arrays provide three major benefits to operations. First, they are more energy efficient. Second, they are easier to maintain: No more rubber belts that break and no more grease for the drive axle and bearings! Finally, the fan array provides redundancy. If the old blower or motor fails, then the unit goes down until it can be repaired. With the retrofit, if one fan from the array fails, the others increase capacity until the broken one can be replaced. You never lose supply from the air handler. This is especially critical in healthcare and laboratory facilities.