Need help finding the right product or a service?

Single ply systems from Tremco Roofing and Building Maintenance are economical, ENERGY STAR qualified and fire-resistant. Whether used for new construction or restoration, they offer excellent UV protection, and their reflectivity can help lower a facility's energy use. Our single ply systems can be adhered without the need of fasteners that can penetrate the roof deck, applied in either hot or cold adhesives, and maintain FM Global approvals. We can also incorporate additional roofing plies with some of our single ply systems to create a "hybrid" roofing system with even greater durability for more rigorous environments or where there is heavy foot traffic. Used in a multi-ply configuration, our single ply membranes are an excellent choice for vegetated roofing systems, both for waterproofing and as a root barrier.

Starting with our flagship product line, the TremPly® KEE and KEE FB (Fleeceback) Single Ply Roofing Systems are designed to provide superior performance and exceptional value. Both systems incorporate proven Ketone Ethylene Ester (KEE), which provides superior flexibility to accommodate building movement, as well as resistance to harmful UV rays and chemicals. Heavy duty reinforcement makes the systems extremely resistant to tears and punctures and combines with maximum seam strength for durability and long-term performance. Their resistance to fungus, algae and fire makes TremPly KEE systems one of the most sustainable roofing systems available.

Tremco’s elastomeric TPA Roof Membrane can be used in a variety of single ply roof system configurations, such as mechanically attached, adhered and ballasted, as well as in situations where other roof systems are not practical due to weight or slope considerations. Used in a multi-ply configuration, it is an excellent choice for vegetated roofing systems both for waterproofing and as a root barrier. The TPA Roof Membrane provides excellent resistance to fire exposure in a variety of roof system configurations and accepts roof movement and thermal shock well. It resists a wide range of harmful pollutants, such as acid rain, falling jet fuel, and other minor industrial pollutants as well as exposure to oil, grease, dirt, and the detergents used to remove these contaminants.

The TremPly® TPO and Max TPO Single Ply Roofing Systems are available as a mechanically attached, fully adhered, ballasted, or heat induction welding system, in fleece-back or non-fleece-back versions. Its hybrid configuration includes multi-ply, hot applied, and low-rise foam applications. The system comes with a full line of readily available, pre-fabricated accessories designed to save time and money during installation. The TremPly TPO Single Ply Roofing System is available in 5-foot and 10-foot-wide sheets that feature heat welded seam integrity and provide an exceptional overall value. The white surface is highly reflective, which could help lower energy use. The system is inherently flexible, eliminating the need for plasticizers, has excellent seam strength, is fungal resistant and provides long term heat and UV resistance.

Single Ply Systems

TremPly TPA Fleeceback Single Ply Roofing System

Tremco Roofing’s TPA Fleeceback Single Ply Roofing System accepts roof movement and thermal shock well.

TremPly® KEE™ Single Ply Roof System

The TremPly® KEE Single Ply Roofing System provides superior performance and exceptional value.

TremPly® TPO Single Ply Roofing System

The TremPly® TPO Single Ply Roofing System is available as a mechanically attached, fully adhered, ballasted, or heat induction welding system, in fleece-back or non-fleece-back versions.

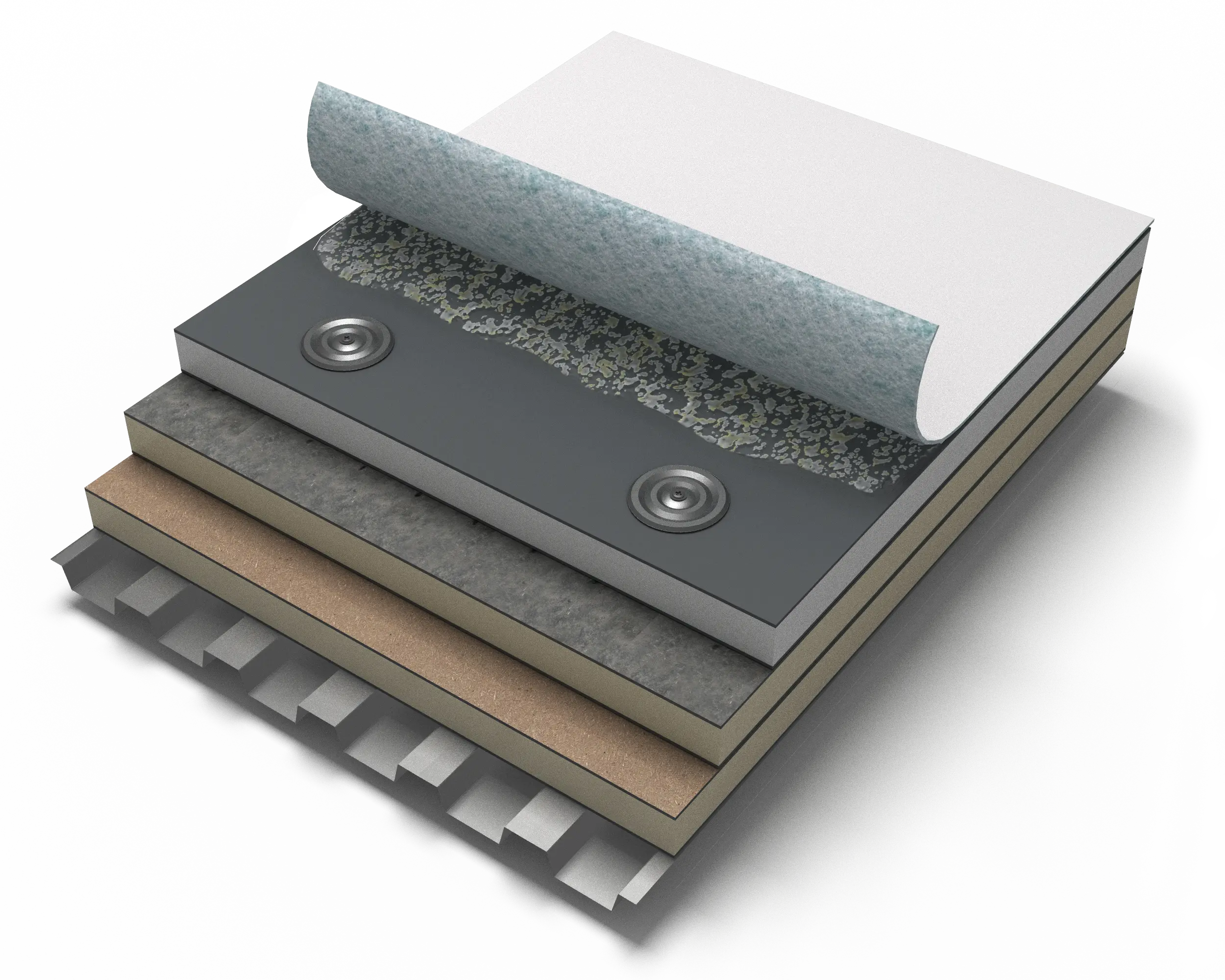

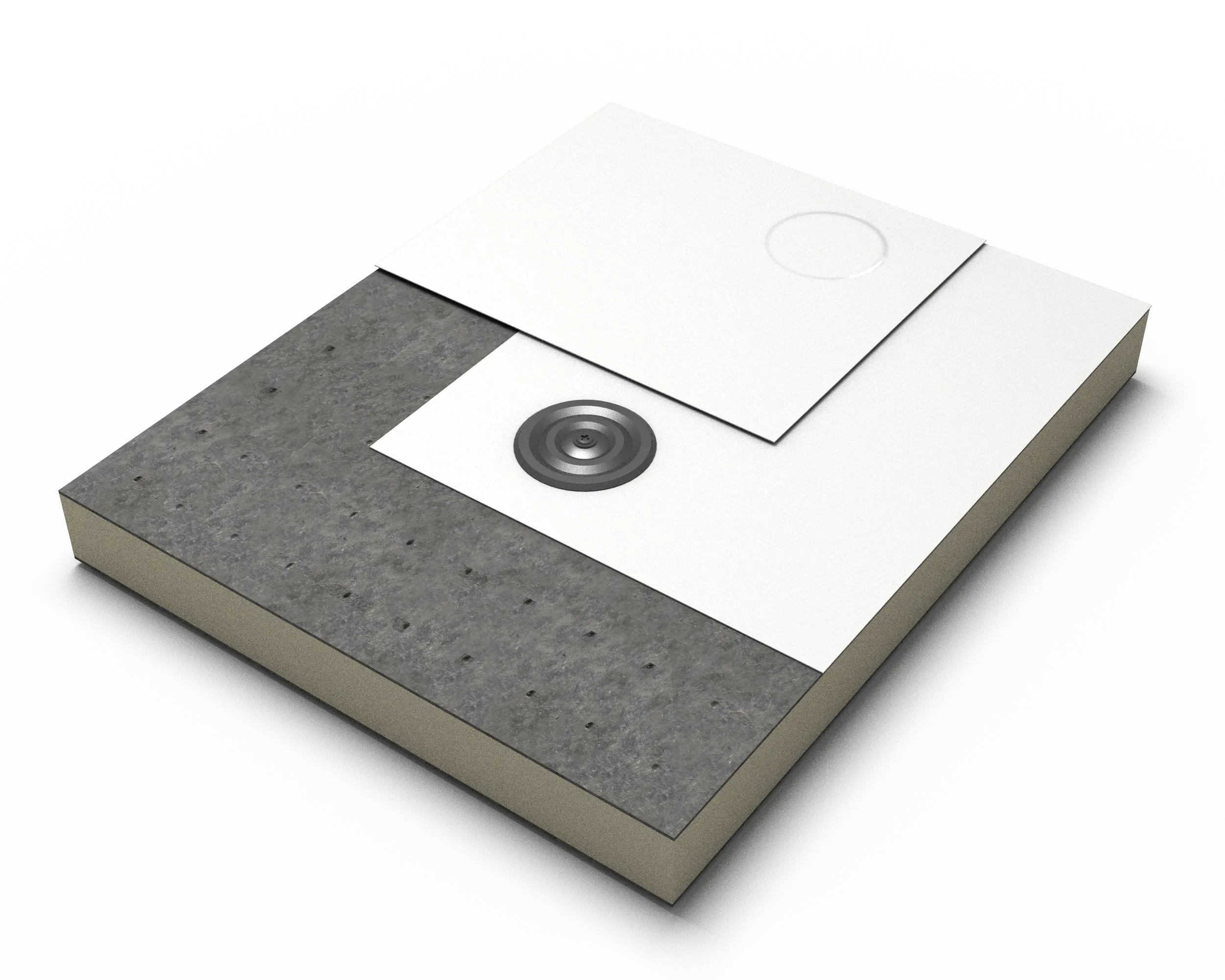

Mechanically Attached System

Tremco’s Single Ply reinforcement is the secret to the membrane’s strength. The yarns are tightly packed together in an intricate pattern, creating one of the toughest reinforcing fabrics available to the commercial roofing industry. This makes TremPly KEE a natural choice for a mechanically attached roof system.

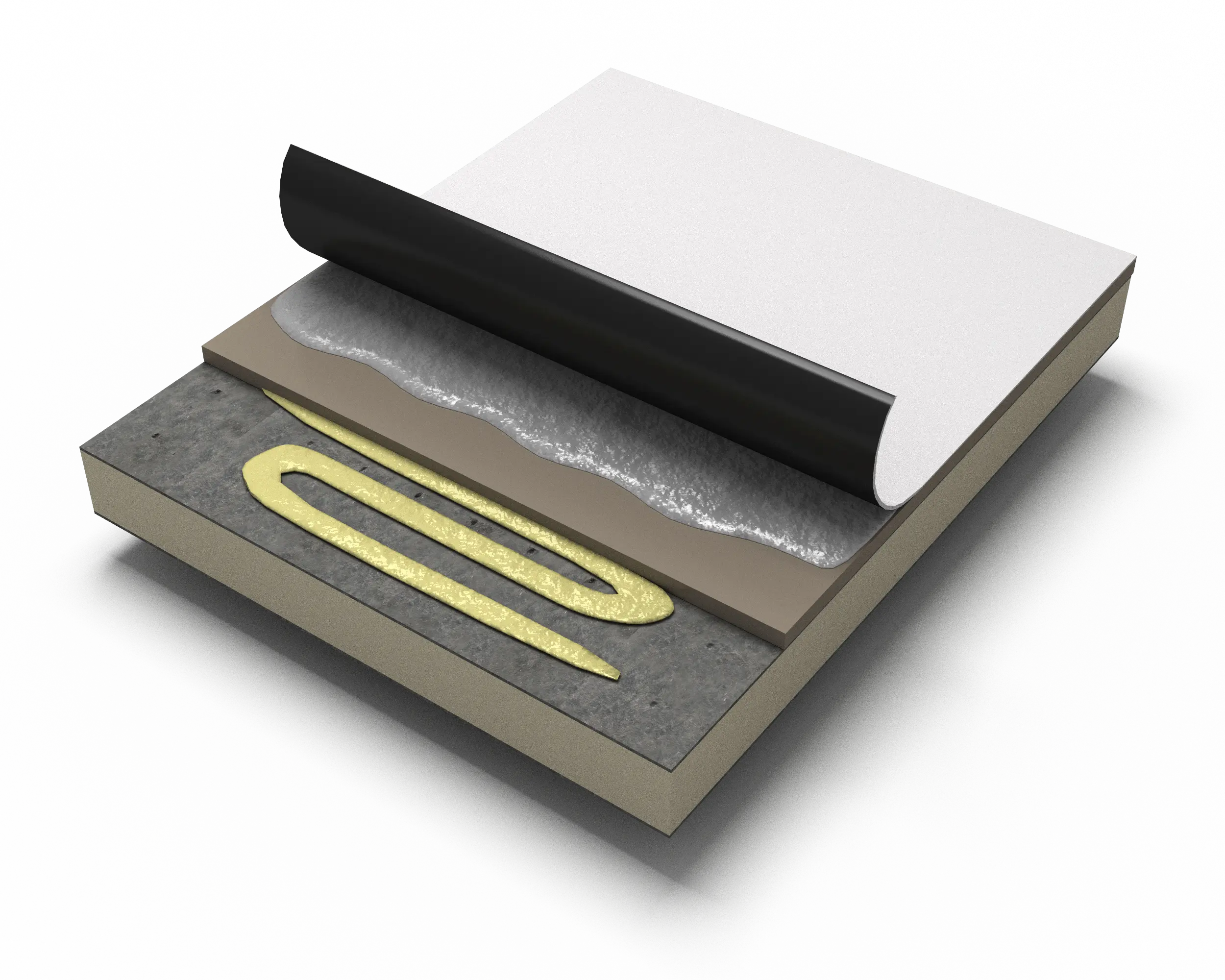

Adhered System

Tremco Roofing also offers an adhered solution for roofs that cannot be mechanically attached, using a select line of high quality TremPly Bonding Adhesives to fully bond your system in place. Systems can be adhered with our Standard Fleeced back adhesives, POWERply® Endure® BIO Adhesive, Tremco LR (Low Rise Foam) Adhesive or hot asphalt.

Color and Size Options

Our Single Ply products are available in colors such as white, gray and tan to meet a building’s design and aesthetic needs and LEED requirements. Rolls are also manufactured in different sizes and thickness with dimensions up to 100” wide by 100’ long.

Exceptional Puncture and Tear Resistance

TremPly KEE’s reinforcement is one of the most densely packed polyester fabrics available. The innovative knit design makes the membrane incredibly puncture- and tear-resistant.

Maximum Seam Strength

Each yarn is fully encapsulated during the manufacturing process, fully bonding the base fabric with the front and back coats. This process inhibits wicking and provides maximum peel resistance and seam integrity, setting our system apart from other manufacturers.

Superior Welding Provides Seam Strength

A balanced back coating on the encapsulated membrane allows for superior welding properties that maximizes seam strength.

Chemical Resistance and Long-Term Flexibility

The chemistry of TremPly KEE incorporates Elvaloy® and many other additives to deliver unmatched resistance to chemicals, making it perfect for manufacturing facilities and food processing plants.

Unrivaled Weatherability

TremPly KEE membranes have exceptional weatherability as a result of the Elvaloy KEE used in its formulation. KEE is a solid plasticizer that does not leach out, keeping the sheet flexible in extreme UV conditions and colder areas with low temperature challenges.

TremPly TPO

Our TremPly TPO roof system offers excellent performance at a great value. TremPly TPO is perfect for your new construction or re- roofing projects. It offers exceptional seam strength and puncture resistance, outstanding long-term weathering and is easy to install. TremPly TPO is available in 45, 60, and 80 mil membranes.

TremPly Max TPO

This system provides advanced protection against heat aging and UV degradation, offering premium performance over standard single ply membranes; it also qualifies as a solar-ready roof membrane. TremPly Max TPO is available in 50, 60, 70, and 80mil membranes.

TremPly TPO & TremPly Max TPO Fleece-back

Our TPO Fleece-back systems offer an alternative to roof tear-off helping you avoid added expenses while still offering installation flexibility that includes mechanically attached, mopped in hot asphalt, or fully adhered with low-rise foam adhesives. TremPly TPO Fleece-back systems are available in both Max and Standard with membranes ranging from 45 to 80 mil.

TremPly TPO Accessories

TremPly TPO ‘s product line also features innovative TPO accessories designed to help save time and labor expenses. The pre-fabricated accessories are easy to install, help reduce wasted material, and eliminate the need to design a workaround for drains, flashing strips, corners, etc